Tow Bars by OST PFAD GmbH

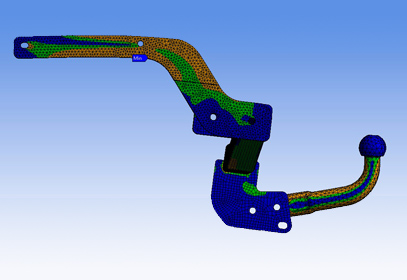

OST PFAD GmbH is one of the leading manufacturers of tow bars. We design and produce tow bars for the world's top automotive brands (OE supplies), as well as under our own SHERIFF trademark.

MP

OST PFAD GmbH is one of the leading manufacturers of tow bars. We design and produce tow bars for the world's top automotive brands (OE supplies), as well as under our own SHERIFF trademark.

Our innovative designs, rigorous testing, and advanced manufacturing capabilities—combined with strong customer support—enable us to provide high-quality, safe products tailored to specific needs. The SHERIFF tow bar catalog features over 500 models, including fixed, easily detachable, and quick-detachable tow bars.

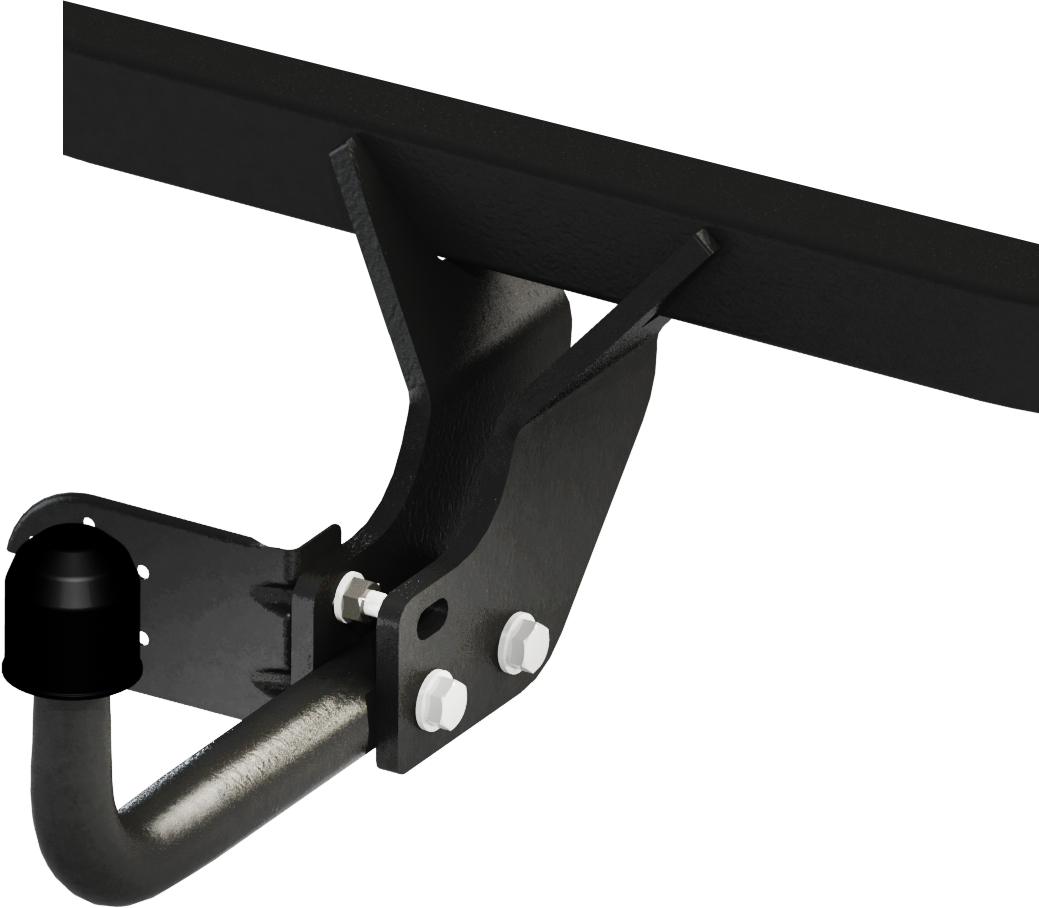

The most cost-effective tow bar system, ideal for frequent towing.

Uses a three-ball locking system for a secure fit while remaining easy to use. Equipped with an anti-theft lock.

A heavy-duty towing solution designed for large payloads.

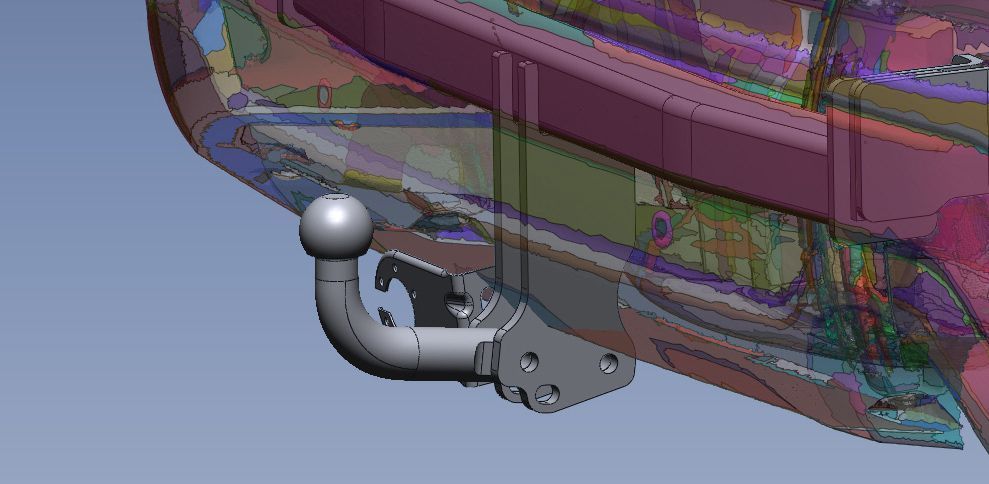

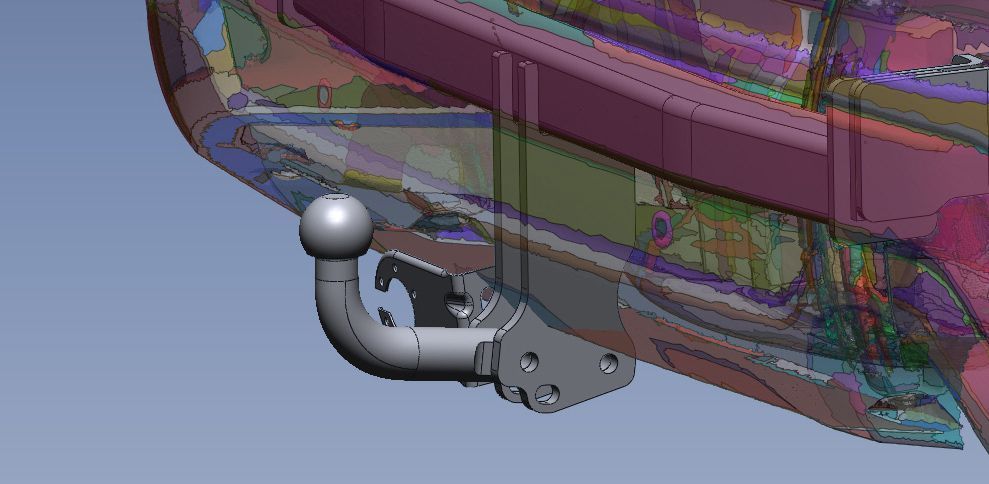

A conventional hitch with a receiver welded to the cross beam, permanently attached to the vehicle’s rear. Economical & functional.

Available sizes:

We use only high-quality metal that meets load requirements, ensuring reliability, durability, and safety in all our tow bars.

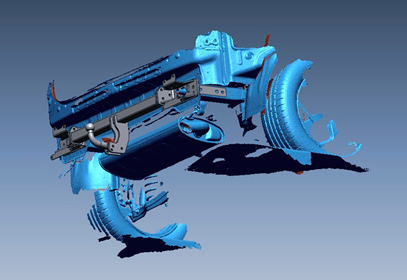

1. Development

— Market research & trend analysis

— Ergonomic design & ease of installation

— Cost optimization & production efficiency

— Reliability & safety assessment

— Compliance with vehicle safety regulations

2. Testing & Certification

— In-house testing laboratory

— Passed climatic tests & salt spray tests (SST)

— Certified: ECE55, IATF 16949

— Proven safety (tested for 2 million cycles)

— High corrosion resistance

3. Manufacturing

4. Coating

Our fully automated coating line ensures maximum protection. Before coating, tow bars undergo:

— Shot blasting for surface preparation

— Chemical cleaning (degreasing, etching)

— Coating thickness control